Relied On Tahoe Instrument Cluster Repair Professionals: Restoring Gauge Precision

Relied On Tahoe Instrument Cluster Repair Professionals: Restoring Gauge Precision

Blog Article

Discover Top Techniques for Reliable Auto Tool Cluster Fixing and Upkeep

In the realm of vehicle upkeep, the elaborate system of an instrument collection plays an essential role in offering motorists with important information about their automobile's performance. Stay tuned to reveal the leading approaches that can streamline the process of car instrument cluster fixing and maintenance, inevitably improving your driving experience and lorry performance.

Common Tool Cluster Issues

Some typical problems may emerge with car tool collections, impacting their functionality and precision. This issue can be triggered by a malfunctioning gas degree sensor or a defective gauge collection. These problems can impede the chauffeur's capability to keep an eye on vital automobile details, stressing the significance of timely instrument collection repair and maintenance to make sure optimal functionality and accuracy while driving. tahoe instrument cluster repair.

Important Devices for Repair Work

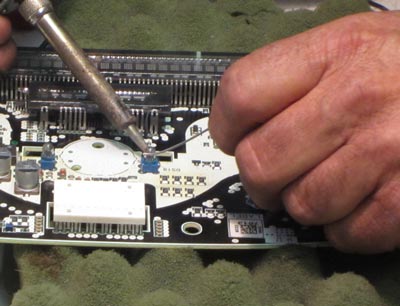

When attending to common instrument collection concerns such as malfunctioning speedometers, unresponsive gas gauges, or dark control panel lights, having the crucial devices for repair is important in making certain precise and effective diagnostics and upkeep. Amongst the primary devices needed for auto tool collection repair service are an electronic multimeter for screening voltage and resistance degrees, a welding torch for taking care of loose links or damaged elements, and a set of screwdrivers for disassembling the cluster. In addition, specialized tools like collection removal hooks may be required for safely removing the collection from the dashboard.

Analysis Methods for Fixing

Utilizing innovative diagnostic methods is important in effectively repairing issues within car tool collections to pinpoint and resolve hidden problems accurately. When encountered with a malfunctioning tool collection, specialists typically rely upon analysis tools like multimeters, check tools, and specialized software to identify the source of the problem. These devices make it possible for technicians to access the cluster's interior systems, fetch error codes, and perform system examinations to diagnose concerns effectively. In addition, strategies such as circuit testing, voltage checks, and signal evaluation play a crucial function in identifying complex digital mistakes within the tool cluster. By following organized analysis treatments and interpreting diagnostic results accurately, service technicians can enhance the read the full info here troubleshooting procedure and make certain the proper performance of the instrument cluster. Regular training and remaining upgraded on the current diagnostic technologies are essential for technicians to effectively repair modern-day instrument collections with innovative functions. A comprehensive analysis technique not just conserves time however also promotes precision in determining and resolving tool cluster problems without delay.

Cleaning and Maintenance Tips

Software Program Updates and Calibration

Calibration is one more vital element of preserving your auto instrument collection. This process entails adjusting the setups and criteria within the software program to make certain that the displayed info, such as rate, fuel level, and temperature level, is reputable and accurate. Correct calibration not just boosts the user experience but also adds to safety and security when traveling by providing vehicle drivers with exact and dependable data.

To guarantee that your automobile tool cluster functions efficiently, it is advised to comply with the manufacturer's guidelines pertaining to software updates and calibration intervals. By remaining proactive this hyperlink in these locations, you can take full advantage of the effectiveness and life-span of your tool cluster.

Final Thought

To conclude, efficient automobile instrument collection repair work and maintenance need a detailed understanding of common concerns, necessary devices, analysis methods, cleaning methods, and software updates. By using these methods, technicians can effectively solve and repair tool cluster problems, making certain exact and reliable efficiency of the find more information automobile's control panel display. Routine upkeep and calibration are essential to avoid future problems and ensuring the appropriate functioning of the tool cluster.

When addressing common tool cluster issues such as malfunctioning speedometers, less competent fuel evaluates, or dim dashboard lights, having the crucial tools for repair work is vital in making certain reliable and accurate diagnostics and maintenance. Among the main tools needed for car tool cluster repair service are an electronic multimeter for screening voltage and resistance degrees, a soldering iron for repairing malfunctioning elements or loose connections, and a collection of screwdrivers for dismantling the collection. Furthermore, specialized tools like collection elimination hooks may be essential for safely separating the cluster from the control panel.

In conclusion, efficient car tool cluster repair and upkeep need a complete understanding of common concerns, necessary tools, diagnostic methods, cleaning approaches, and software updates. Normal upkeep and calibration are key to preventing future concerns and making certain the proper performance of the tool cluster.

Report this page